Wamkelekile kwi CHUANGRONG

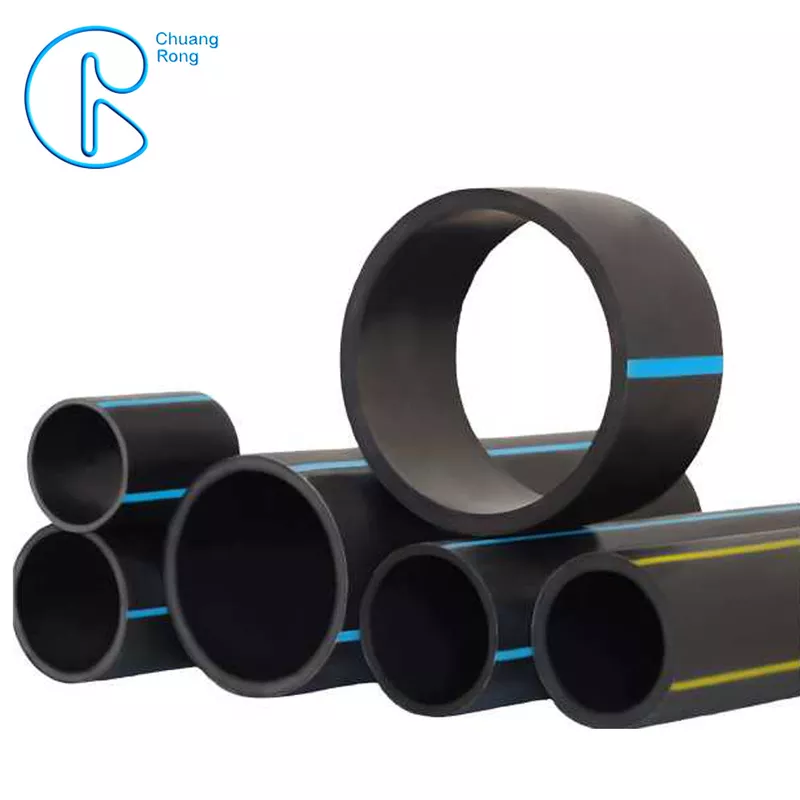

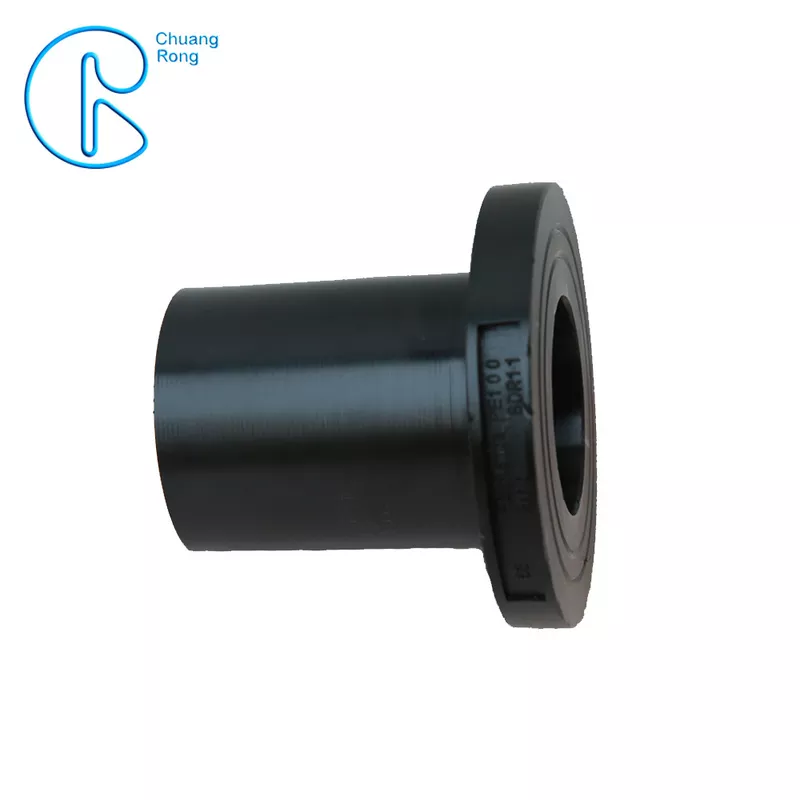

Abathengisi beOyile ye-Electro-Fusion eWeldable Joint/Fitting for PE Pipe/Waste Water Pipe/Pre-Insulated

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho weemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-REALISTIC, EZISEBENZAYO NEZINTO EZINTSHA umoya wabasebenzi kubathengisi be-Wholesale ye-Electro-Fusion Weldable Joint/Fatting for PE Pipe/Waste Water Pipe/Pre-Insulated Pipe, Wamkelekile ngokufudumeleyo ukusebenzisana nathi! siya kuqhubeka nokubonelela ngempahla ekumgangatho ophezulu kunye neendleko zokhuphiswano.

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho weemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye neYENENE, OKUSEBENZAYO KUNYE NEZINTO EZINTSHA zabasebenzi.I-China Pipeline yokuvalwa ngokudibeneyo kunye ne-Electro Fusion Wrap, Sinenkqubo engqongqo kunye nepheleleyo yokulawula umgangatho, eqinisekisa ukuba imveliso nganye inokuhlangabezana neemfuno zomgangatho wabathengi. Ngaphandle koko, zonke iimveliso zethu ziye zahlolwa ngokungqongqo ngaphambi kokuthunyelwa.

Ulwazi lwemveliso

●Amandla e-Welding: 3.5KW, 2.2KW adibana kuphela nesigaba esisodwa se-220V igalelo lombane;

● Izincedisi ozikhethelayo: S: S: ukufunda iskena; G: Indawo yeGPS; P: umshicileli;

Qaphela: Ukufezekiswa komsebenzi wokuskena ikhowudi yebha, ukuprinta kunye neGPS kufuneka kuthengwe izixhobo ezihambelanayo.

| ◇ Iyunithi yolawulo yeSCM ephucukileyo, useto oluninzi lweparamitha, umlinganiselo kunye nomsebenzi wokukhusela |

| ◇ Umboniso oqaqambileyo weLCD, ukusebenza kwesiTshayina/IsiNgesi, ujongano olunobuhlobo lomntu nomatshini |

| ◇ Unikezelo olubanzi lwamandla kunye negalelo lombane, lulungele ngokupheleleyo amaza ombane wombane |

| ◇ Amandla achanekileyo aphezulu, ukulawula ixesha, ukuqinisekisa umgangatho we-welding |

| ◇ Ixesha lokuphendula lemveliso ngokukhawuleza (500??800ms), uzinzo olucolekileyo xa umbane uqhawuka |

| ◇ Ngomsebenzi wezigaba ezili-10 zokuwelda okucwangcisiweyo, ezifanelekileyo kwiimfuno ezahlukeneyo zokuwelda kwezifakelo. |

| ◇ Umthamo omkhulu wogcino lwedatum yewelding, indlela elula yokufaka iiparamitha zewelding |

| ◇ Uyilo olugqibeleleyo kunye nomsebenzi wezandla we-SMT welding, Nciphisa impazamo yeseti epheleleyo |

| ◇ Umsebenzi wokukhusela ngokuchasene ne-over-current, over-voltage and overload njl. |

| ◇ Uyilo oludibeneyo, umthamo omncinci kunye nobunzima obulula |

Iimpawu zobuGcisa

| Uluhlu lokuSebenza | 20-200mm |

| Umbane wemveliso yeWelding | 8-48V |

| Isigaba esinye | 230V |

| Ukunikezwa Amandla | 50-60Hz |

| Max.afunxa amandla | 4000W |

| Max.imveliso yangoku | 100A |

| 60% Imveliso yomjikelo | 60A |

| Umthamo weMemori | 500 ingxelo |

| Isidanga soKhuseleko | IP54 |

| Umatshini wokulinganisa (WxDxH) | 263X240X300mm |

| Icala elithwele imilinganiselo (WxDxH) | 352x188x341 |

| Ubunzima | 9Kg |

Iqhosha-cofa

| Iqhosha-cofa | Igama | Inkcazo yomsebenzi |

| OK | Isiqinisekiso | Qinisekisa |

| I-ESC | Phuma | Rhoxisa |

| Ç | Nyusa | Imenyu phezulu / Ukonyuka kwedatha |

| È | Nciphisa | Imenyu phantsi / Idatha iyancipha |

| Æ | Ukutshintsha kwasekunene | Imenyu yasekunene shift/Indawo elungisiweyo shift yasekunene |

| Å | Ishifti yasekhohlo | Imenyu yasekhohlo shift/Indawo elungisiweyo ekhohlo shift |

Iparameter esebenzayo

| Inombolo yemenyu. | Igama | Uluhlu | Ukuhlala kukho | Uphawu lwekhibhodi |

| Imenyu yeParameter 1: iiparamitha ze-welding | ||||

| 1.01 | Ukukhetha indlela yokulawula | Amandla ombane rhoqo / akhoyo ngoku rhoqo | Umbane othe rhoqo | R/W |

| 1.02 | Izigaba zokuwelda | 1~6 | 1 | |

| 1.03 | Ukuxhathisa imibhobho | 0.00-19.99 | 0 | |

| 1.04 | Ukuwelda para. kwe 1stisigaba | 0~Ikaliwe | 0 | |

| 1.05 | Ixesha le-welding ye-1stisigaba | 0~9999 | 0 | |

| 1.06 | Ukuwelda para. kwe2ndisigaba | 0~Ikaliwe | 0 | |

| 1.07 | Ixesha le-welding ye-2ndisigaba | 0~9999 | ||

| 0 | ||||

| 1.08 | Ukuwelda para. kwe3rdisigaba | 0~Ikaliwe | 0 | |

| 1.09 | Ixesha le-Welding yi-3rdisigaba | 0~9999 | 0 | |

| 1.10 | Ukuwelda para. kwe4thisigaba | 0~Ikaliwe | 0 | |

| 1.11 | Ixesha le-Welding ye-4thisigaba | 0~9999 | 0 | |

| 1.12 | Ukuwelda para. ye5thisigaba | 0~Ikaliwe | 0 | |

| 1.13 | Ixesha le-Welding yi-5thisigaba | 0~9999 | 0 | |

| 1.14 | Ukuwelda para. ye6thisigaba | 0~Ikaliwe | 0 | |

| 1.15 | Ixesha le-Welding yi-6thisigaba | 0~9999 | 0 | |

| 1.16 | Ixesha lokupholisa | 0~9999 | 0 | |

| Imenyu yeParameter 2: Iiparamitha zomsebenzi weFomula | ||||

| 2.01 | Inombolo yefomula. | 0~20 | 0 | R/W |

| 2.02 | Uhlobo lombhobho wefomula | 0~32000 | 0 | |

| 2.03 | Ukumelana nemibhobho yefomula | 0.00-19.99 | 0 | |

| 2.04 | Imo yolawulo lwefomula | Amandla ombane rhoqo / akhoyo ngoku rhoqo | Umbane othe rhoqo | |

| 2.05 | Izigaba ze-formula welding | 1~6 | 1 | |

| 2.06 | Ukuwelda para. kwe 1stisigaba | 0~Ikaliwe | 0 | |

| 2.07 | Ixesha le-welding ye-1stisigaba | 0~9999 | 0 | |

| 2.08 | Ukuwelda para. kwe2ndisigaba | 0~Ikaliwe | 0 0 | |

| 2.09 | Ixesha le-welding ye-2ndisigaba | 0~9999 | ||

| 0 | ||||

| 2.10 | Ukuwelda para. kwe3rdisigaba | 0~Ikaliwe | 0 | |

| 2.11 | Ixesha le-Welding yi-3rdisigaba | 0~9999 | 0 | |

| 2.12 | Ukuwelda para. kwe4thisigaba | 0~Ikaliwe | 0 | |

| 2.13 | Ixesha le-Welding ye-4thisigaba | 0~9999 | 0 | |

| 2.14 | Ukuwelda para. ye5thisigaba | 0~Ikaliwe | 0 | |

| 2.15 | Ixesha le-Welding yi-5thisigaba | 0~9999 | 0 | |

| 2.16 | Ukuwelda para. ye6thisigaba | 0~Ikaliwe | 0 | |

| 2.17 | Ixesha le-Welding yi-6thisigaba | 0~9999 | 0 | |

| 2.18 | Ixesha lokupholisa ifomula | 0~9999 | 0 | |

| 2.19 | Gcina ifomula yangoku | 0~1 | 0 | |

| Imenyu yeParameter3: iparameters setting | ||||

| 3.01 | Ubushushu obuqhelekileyo bendawo | 0.0~50.0℃ | 20℃ | R/W |

| 3.02 | Imbuyekezo yobushushu be-Ambient | 0.00%~0.09% | 0.02% | |

| 3.03 | Ukumiswa kwe-welding kuvuleleke | 0~1 | 0 | |

| 3.04 | Ukuchongwa kombhobho kuvuleleke | 0~1 | 0 | |

| 3.05 | Ukuphinda kuphindwe kabini ukusetwa kombane | 1.0-15.0 | 10.0 | |

| 3.06 | Ummiselo wohlobo lwekhowudi yebha | 0~1 | 0 | |

| 3.07 | Ukuchonga ukuchasa kuvuleleke | 0~1 | 0 | |

| 3.08 | Uluhlu lokuchasa | 0~±30% | ±15% | |

| 3.09 | Ulwimi | 0~2 | 0 | |

| 3.10 | Unyaka | 1~99 | 16 | |

| 3.11 | Inyanga | 1 ~12 | 8 | |

| 3.12 | Usuku | 1 ~31 | 8 | |

| 3.13 | Yure | 0~23 | 8 | |

| 3.14 | Mzuzu | 0~59 | 8 | |

| 3.15 | Ulungiselelo lwasefektri | 0~9999 | 1000 | |

| Imenyu yeparamitha 5: isathelayithi ifunyenwe useto lweparamitha | ||||

| 5.01 | Umiselo lwezowuni yexesha langoku | -12+12 | 8 | R/W |

| 5.02 | Uhlaziyo lwexesha leSatellite | 0~1 | 0 | |

| 5.03 | Inombolo yesathelayithi yangoku | - | - | R |

| Imenyu yeParameter 6: ukusetwa kweparamitha yobunjineli | ||||

| 6.01 | Ubunjineli Nomb. | Ukudityaniswa koonobumba abangama-20 kunye namanani | - | R/W |

| 6.02 | Inombolo yeprojekthi. | Ukudityaniswa koonobumba abangama-20 kunye namanani | - | |

| 6.03 | Welder No. | Ukudityaniswa kwamanani ama-6 | - | |

| 6.04 | Ukudibanisa i-Welding No. | Ukudityaniswa kwamanani ama-6 | - | |

| 6.05 | Uhlobo lombhobho | Ukudityaniswa koonobumba abali-10 kunye namanani | - | |

| 6.06 | Umzi-mveliso wokufakelwa kwemibhobho | Ukudityaniswa koonobumba aba-5 kunye namanani | - | |

| 6.07 | Umbhobho ububanzi | Ukudityaniswa koonobumba aba-5 kunye namanani | - | |

| 6.08 | Umbhobho wokufaka i-SDR | 33;26;17.6;17;13.6;11;9;Akukho nanye | Akukho nanye | |

| 6.09 | Imathiriyeli yombhobho | PE80/PE100/ Akukho | Akukho nanye | |

| 6.10 | Umatshini wokuwelda uNombolo. | Ukudityaniswa koonobumba abangama-25 kunye namanani | - | |

Iworkshop

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho weemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-REALISTIC, EZISEBENZAYO NEZINTO EZINTSHA umoya wabasebenzi kubathengisi be-Wholesale ye-Electro-Fusion Weldable Joint/Fatting for PE Pipe/Waste Water Pipe/Pre-Insulated Pipe, Wamkelekile ngokufudumeleyo ukusebenzisana nathi! siya kuqhubeka nokubonelela ngempahla ekumgangatho ophezulu kunye neendleko zokhuphiswano.

Sihlala sikholelwa ukuba umlingiswa womntu uthatha isigqibo somgangatho weemveliso, iinkcukacha zithatha isigqibo somgangatho ophezulu wemveliso, kunye ne-REALISTIC, EZISEBENZAYO NEZINTO EZINTSHA umoya wabasebenzi kubathengisi be-Wholesale ye-Electro-Fusion Weldable Joint/Fatting for PE Pipe/Waste Water Pipe/Pre-Insulated Pipe, Wamkelekile ngokufudumeleyo ukusebenzisana nathi! siya kuqhubeka nokubonelela ngempahla ekumgangatho ophezulu kunye neendleko zokhuphiswano.

Abathengisi beWholesale yeI-China Pipeline yokuvalwa ngokudibeneyo kunye ne-Electro Fusion Wrap, Sinenkqubo engqongqo kunye nepheleleyo yokulawula umgangatho, eqinisekisa ukuba imveliso nganye inokuhlangabezana neemfuno zomgangatho wabathengi. Ngaphandle koko, zonke iimveliso zethu ziye zahlolwa ngokungqongqo ngaphambi kokuthunyelwa.

Thumela umyalezo wakho kuthi:

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

I-Skype

-

Phezulu