Wamkelekile kwi CHUANGRONG

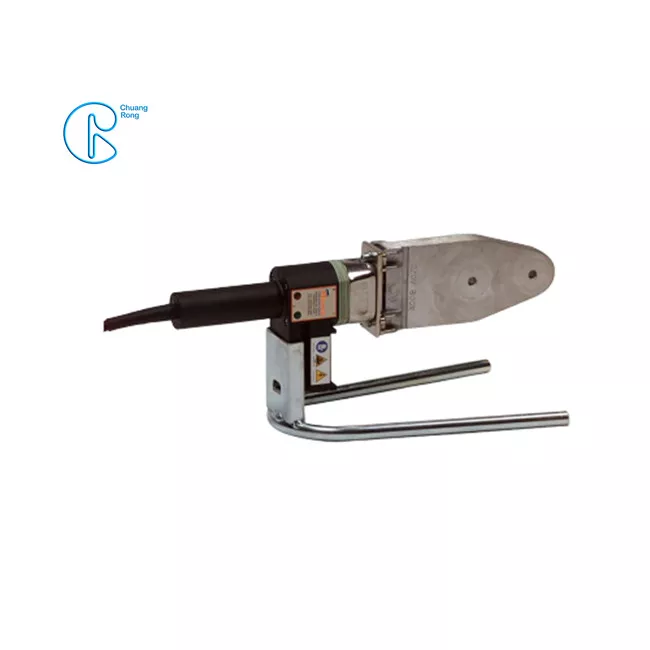

20-32mm Poly Pipe Socket Fusion Machine Handle Small PPR Welding Machine

Ulwazi olusisiseko

| INOMBOLO yoMfanekiso. | R 32mm | Ubukhulu beDayamitha: | 32mm |

|---|---|---|---|

| Amandla afunxiweyo: | 800W | Ubungakanani: | 175*50*360mm |

| Ubushushu bokusebenza: | Tfe:260oc(+/-10oc);Te:180oc~290oc | Ipakethe yezoThutho: | Ibhokisi yePlastiki |

Ingcaciso yeMveliso

I-manual soket welders ye-jointing pipe kunye nezixhobo, ngokuthobela imilinganiselo esebenzayo. Babonisa ipleyiti yokufudumeza i-aluminium kunye ne-practical, i-heater-insulated handle handle. Ziyakwazi ukuwelda i-HDPE, i-PP, i-PPR, i-PVDF imibhobho kunye ne-fitngs, kwaye ibonakaliswe ngeeshaphu ezahlukeneyo kunye noluhlu olusebenzayo, olulungele izicelo ezahlukeneyo. Ziyafumaneka kunye ne-electronic themmoregulator (TE) ehlengahlengiswayo, okanye ngethermostat yombane esisigxina (TFE).

Iinkcukacha zomatshini wokuwelda wePPR

| Izinto eziphathekayo | PE, PP, PP-R, PVDF | ||

| Ubukhulu beDayamitha | 32mm | ||

| Amandla afunxiweyo | 800W | ||

| Ubunzima | 1.82 kg | ||

| Ubungakanani | 175*50*360mm | ||

| Ubushushu bokusebenza | TFE:260ºC(+/-10ºC);TE:180ºC~290ºC | ||

| Ubushushu obugciniwe | -5 ~ 40ºC | ||

| Ukunikezwa Amandla | TE:230V-Single isigaba 50/60Hz;TFE:110~230V Isigaba Single 50/60 Hz | ||

IMIYALELO YOKUSEBENZA

4.1. Khangela ukuba amandla ombane ombane ayafana na

Umbane ochazwe kwi-socket fusion welding

ipleyiti yomatshini.

4.2. IZIXHOBO ZOKUSEBENZISA I-SOCKET FUSION

UMTSHINI WOKUSHISA

a b

a) Ifolokhwe.Ifanelekile ukuwelda emgangathweni.

b) Isibiyeli sebhentshi. Ngomsebenzi webhentshi.

c) Iqonga. Enye indlela kwifolokhwe.

4.3. Faka umatshini wokuwelda wesokethi kwi

isixhobo esikhethiweyo.

4.4. Faka amatyholo e-M/F ngokweemfuno.

QAPHELA: Umphezulu wehlathi elidibana nomatshini we-welding kufuneka ugcinwe ucocekile ngamaxesha onke.

4.5. Bamba amatyholo ngokuqinileyo kumatshini we-Socket fusion welding (usebenzisa i-wrench) ukufumana utshintshiselwano oluyimfuneko lobushushu lobushushu.

ezifunekayo ematyholweni

A: Isitshisi esinehexagonal

B: Iyunithi yephini yamatyholo

4.6. Qhagamshelana kwizinto ezingundoqo

4.6.1. TE IMIBONELO

|

| Bonisa LO v emva amandla kwi.Emva kwemizuzu eyi-10-20, ipleyiti yokufudumeza iqala ukubonisa ubushushu, ifikelele kwiqondo lobushushu elibekiweyo uze uzinziseCofa isitshixo sokuseta ukungena kwimo yobushushu kwaye usete ubushushu ngokwe + -.Cofa - ukutshintsha imo. |

4.7. I-10 - 15 imizuzu emva kokuba umatshini we-socket welding welding uvuliwe (okanye nayiphi na imeko xa ufikelele kwiqondo lokushisa lokusebenza).

Bonke oomatshini bokuwelda beplastiki ababonelelweyo babekwe kubushushu obumalunga nama-260° C.

Khangela ukuba umda wehlathi uchazwe ngumvelisi wombhobho ukuba udityaniswe.Sebenzisa a

ithemometha yedijithali

Ulungelelaniso oluchanekileyo lobushushu phakathi kwe-180° C

kunye ne-290 ° C inokwenzeka. Sebenzisa ithemometha yedijithali

ukulinganisa iiyantlukwano ezincinci

Ukupakisha

Okunye

Thumela umyalezo wakho kuthi:

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

I-Skype

-

Phezulu