Wamkelekile kwi CHUANGRONG

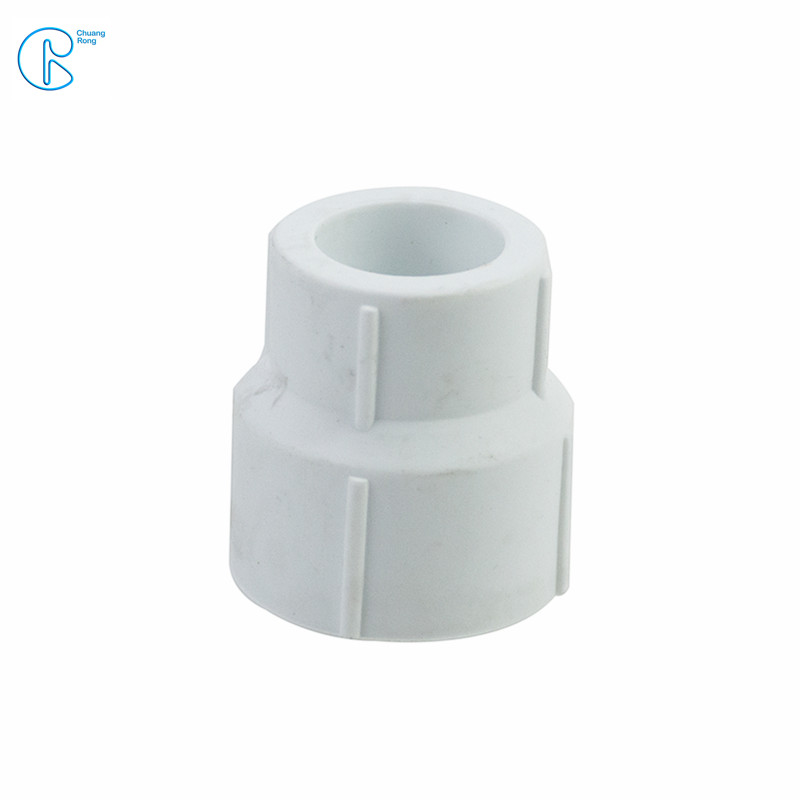

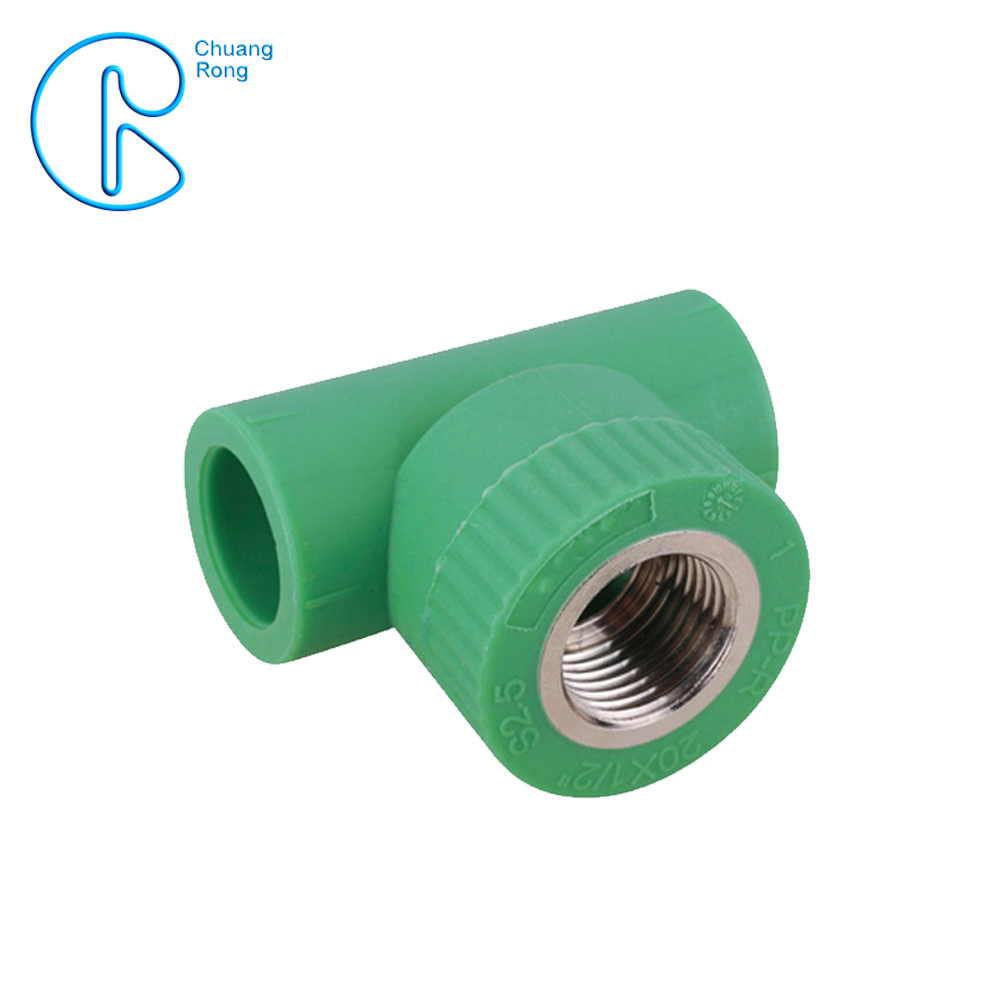

I-Green PPR Reducer kwi-Pressure 25 yoKufudumeza / i-Air Conditioning System

Iinkcukacha zolwazi

| Igama lemveliso: | I-PPR yokunciphisa | Ubume: | Isinciphisi |

|---|---|---|---|

| IKhowudi yeNtloko: | Umjikelo | Umbala: | Luhlaza |

| Uphawu: | CR | Ubushushu beMveliso: | -40 – +95°C |

Ingcaciso yeMveliso

I-Green PPR Reducer kwi-Pressure 25 yoKufudumeza / i-Air Conditioning System

Qonda uqhagamshelo phakathi kwemibhobho okanye ukufakelwa kobubanzi obahlukeneyo, uqhagamshelo lwe-welder socket, olulungele kwaye lulula, lukhuselekile kwaye lunobuhlobo nokusingqongileyo.

| Iipropati Zomzimba | Isiqhelo Ixabiso* | Iyunithi | TestMethod | |

| Ukuxinana | 905 | kg/m3 | ISO 1183 | |

| Melt Flow Rate | (230℃/2.16kg) | 0.25 | g/10 imiz | ISO 1133 |

| Uxinzelelo lwe-Tensile kwi-Yield | (50 mm/min) | 25 | MPa | ISO 527-2 |

| Uxinzelelo lwe-Tensile kwi-Ield | (50 mm/min) | 10 | % | ISO 527-2 |

| Imodyuli yeElasticity kwiTension | (1 mm/min) | 900 | MPa | ISO527 |

| I-Charpy Impact Amandla, iphawulwe | (+23℃) | 40 | kJ/m2 | ISO 179/1eA |

| I-Charpy Impact Amandla, iphawulwe | (0℃) | 4 | kJ/m2 | ISO 179/1eA |

| I-Charpy Impact Amandla, ephawulweyo | (-20℃) | 2 | kJ/m2 | ISO 179/1eA |

| Mean Linear Thermal Coefficient of Expansion from 0°C ukuya 70℃ | 1.5 | *10-4K-1 | DIN 53752 | |

| I-Thermal Conductivity | 0.24 | WK-1m-1 | I-DIN 52612 icandelo loku-1 | |

Ingcaciso

| Descrlption | d | d1 | D | D1 | L |

| dn25x20 | 20 | 20 | 34 | 28 | 37 |

| i32x20 | 32 | 20 | 43 | 28 | 41 |

| d032x20 | 32 | 20 | 43 | 34 | 53 |

| dn40x20 | 40 | 20 | 53 | 28 | 48 |

| dn40x20 | 40 | 20 | 53 | 34 | 48 |

| dn40x32 | 40 | 32 | 53 | 43 | 63 |

| dn50x20 | 50 | 20 | 67 | 28 | 56 |

| dn50x20 | 50 | 20 | 67 | 34 | 54 |

| i50x32 | 50 | 02 | 67 | 43 | 54 |

| dn50x40 | 50 | 40 | 67 | 43 | 54 |

| dn63x20 | 63 | 20 | 84 | 28 | 68 |

| dn63x20 | 63 | 20 | 84 | 34 | 66 |

| dn63x32 | 63 | 32 | 84 | 43 | 66 |

| dn63x40 | 63 | 40 | 84 | 53 | 66 |

| dn63x50 | 63 | 50 | 84 | 67 | 66 |

| dn75x40 | 75 | 40 | 100 | 53 | 68 |

| dn75x50 | 75 | 50 | 100 | 67 | 74 |

| dn75x63 | 75 | 63 | 100 | 84 | 70 |

| dn90x63 | 90 | 63 | 120 | 84 | 82 |

| dn90x75 | 90 | 75 | 120 | 100 | 83 |

| dn110x63 | 110 | 63 | 148 | 84 | 88 |

| dn110x75 | 110 | 75 | 148 | 100 | 98 |

| dn110x90 | 110 | 90 | 148 | 120 | 95 |

| dn125x110 | 125 | 110 | 150 | 141 | 100 |

| dn160x125 | 180 | 125 | 204 | 150 | 110 |

Inzuzo

I-Perfect Thermal Fusion Joints: Indlela ekhethekileyo yokuwelda i-socket-fusion idala i-monolithic, i-joint-proof-proof joint eyomeleleyo njengombhobho ngokwawo, eqinisekisa ukunyaniseka kwenkqubo yokugqibela.

Ukumelana nobushushu obukhethekileyo: Kukulungele ukusetyenziswa kwamanzi ashushu nabandayo. ekwaziyo ukumelana nobushushu bokusebenza obuqhubekayo ukuya kuthi ga kwi-70℃ kunye namaqondo obushushu aphezulu exesha elifutshane.

Ucoceko oluPhezulu kunye nokucoceka kwamanzi: Izinto ezingasebenziyo zithintela ukubola kunye nokulinganisa, ziqinisekisa ukuba akukho ncasa, ivumba, okanye ukungcoliseka kwamanzi okusela, kunye nokugcina umgangatho wamanzi aphezulu.

Ubomi beNkonzo ende kunye noKuhlala ixesha elide: Ukuchasana okugqwesileyo kwimichiza kunye ne-electrochemical corrosion iqinisekisa ubomi benkonzo engaphezulu kwe-50 vears phantsi kweemeko eziqhelekileyo zokusebenza.

Ukonga amandla kunye nokuKhusela; Ukuhanjiswa kwe-thermal ephantsi kunciphisa ukulahleka kobushushu kwimigca yamanzi ashushu, ukonga amandla, kwaye kuthintele ukuxinana komphezulu kwimigca yamanzi abandayo.

Ubunzima bokukhanya kunye noFakelo olulula: Ilula kakhulu kuneepio zetsimbi. ukwenza uthutho kunye nofakelo ngokukhawuleza, i-easrer, kunye neendleko ezisebenzayo.

Isicelo

I-CHUANGRONG ineqela labasebenzi elibalaseleyo elinamava atyebileyo. Inqununu yayo yiMfezeko, iProfessional and Efficient. Iseke ubudlelwane boshishino namazwe angaphezu kwama-80 kunye nemimandla kushishino olunxulumeneyo. Ezinje ngeUnited States, Chile, Guyana, United Arab Emirates, Saudi Arabia, Indonesia, Malaysia, Bangladesh, Mongolia, Russia, Afrika njalo njalo.

Wamkelekile ukuba uqhagamshelane nathi ngeenkcukacha zeemveliso kunye nenkonzo yobungcali.

Nceda uthumele i-imeyile ku: chuangrong@cdchuangrong.comokanye uMnxeba:+ 86-28-84319855

Thumela umyalezo wakho kuthi:

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

I-Skype

-

Phezulu