Wamkelekile kwi CHUANGRONG

20-1000mm 15KW Electrofusion Welding Machine Usebenzisa iHDPE Plastic Pipe Joining heater

Iinkcukacha zolwazi

I-CHUANGRONG lishishini lesabelo kunye nenkampani yorhwebo ehlangeneyo, eyasekwa ngo-2005 egxile kwimveliso yemveliso.Imibhobho ye-HDPE, iFittings & Valves, iMibhobho yePPR, iFittings & Valves, iPP compression fittings & Valves, kunye nokuthengiswa koomatshini bokuWelding bePlastiki, Izixhobo zePipe, iPipe Repair Clampkwaye nangokunjalo.

15KW Electrofusion Welding Machine with MCU Control

| Ukusetyenziswa: | Uqhagamshelo lweMibhobho ye-Electrofusion | Inkonzo yasemva kokuthengisa ebonelelweyo: | Amacandelo asimahla, uFakelo lweNdawo, ukuThunyelwa kunye noQeqesho, uLondolozo lweNdawo kunye neNkonzo yokuLungisa, iNkxaso ye-Intanethi, iNkxaso yoBugcisa beVidiyo |

|---|---|---|---|

| Iwaranti: | Unyaka omnye | Uluhlu lokuSebenza: | 20-1000mm, 15KW |

| Umbane ophuma kwiWelding: | 8-75V | Uhlobo Lwepakethe: | Ibhokisi yomthi |

Ingcaciso yeMveliso

* I-MCU yezinga eliphezulu isetyenziswe njengengundoqo yokulawula, kunye nokusekwa kwepharamitha eninzi, ukulinganisa kunye nomsebenzi ogqibeleleyo wokukhusela;

*Ukukhanya okuphezulu kwekristale yolwelo olubonakalayo, inkxaso yeelwimi ezininzi, ukusebenza kweqhosha lokuchukumisa, ujongano olusebenzayo lomatshini womntu;

*Unikezelo lwamandla abanzi kunye negalelo lombane, olulungele inqanaba lothungelwano lombane kwindawo leyo;

* Ulawulo oluchanekileyo oluphezulu kumandla ombane kunye nexesha, qinisekisa umgangatho we-welding;

*Ixesha lokuphendula ngokukhawuleza xa unikezelo lwamandla luqhekeka, uzinzo oluphezulu;

* Inkxaso yerekhodi ye-welding yedisk;

*Ukuxhasa iparamitha yefomula yedisk yokungenisa;

*Ukuxhasa umshicileli ophathwayo we-USB, ushicilele irekhodi ye-welding;

*Ngokuchonga ngokuzenzekelayo umsebenzi wombhobho ohambelanayo;

*Umsebenzi wokhuseleko ophindwe kabini;

* Ukuya kuthi ga kwizigaba ezi-6 ezicwangcisiweyo zokuwelda, ziyakwazi ukuziqhelanisa neemfuno zokuwelda imibhobho eyahlukeneyo;

*Ukuxhasa igalelo leeparamitha zewelding ezahlukeneyo: igalelo lezandla, ukutsalwa kwefomula, igalelo lokuskena ikhowudi yebha;

*Ibhodi yokulawula ithatha itekhnoloji ye-welding ye-SMT ukunciphisa izinga lokungaphumeleli komatshini wonke.

I-CHUANGRONG ineqela labasebenzi elibalaseleyo elinamava atyebileyo. Inqununu yayo yiMfezeko, iProfessional and Efficient. Iseke ubudlelwane boshishino namazwe angaphezu kwama-80 kunye nemimandla kushishino olunxulumeneyo. Ezinje ngeUnited States, Chile, Guyana, United Arab Emirates, Saudi Arabia, Indonesia, Malaysia, Bangladesh, Mongolia, Russia, Afrika njalo njalo.

Ukuba unayo nayiphi na imibuzo, ungaziva ukhululekile ukuqhagamshelana nathi nangaliphi na ixesha.

Wamkelekile ukuba uqhagamshelane nathi ngeenkcukacha zeemveliso kunye nenkonzo yobungcali.

Nceda uthumele i-imeyile ku:chuangrong@cdchuangrong.com okanye uMnxeba:+ 86-28-84319855

| Igalelo lombane | Ilinganiswe igalelo lombane | 220V±20% |

| Ilinganiswe ngamaza egalelo | 45-65Hz | |

| Unikezelo lwamandla ophumayo | Ilinganiswe umthamo wombane | Jonga kuhlobo lwenkcazo |

| Amandla emveliso | Jonga kuhlobo lwenkcazo | |

| Iimpawu zokulawula | Imo yokulawula | I-voltage eqhubekayo, yangoku rhoqo |

| Ubungakanani bombane obuchanekileyo rhoqo | ≤±0.5% | |

| Ukuchaneka kolawulo lwexesha | ≤±0.1% | |

| Ukuchaneka komlinganiselo wobushushu | ≤1% | |

| Skena ikhowudi yebha | Skena ikhowudi yebhayithi engama-24 ihambelane ne-ISO 13950-2007 | |

| I-Ambient | Ubushushu obugciniwe | -20℃50℃ |

| Ubushushu bokugcina | -30℃70℃ | |

| Ukufuma | 20%~90%RH, akukho condensation | |

| Ukungcangcazela | <0.5G, akukho vibration enobundlobongela kunye nefuthe | |

| Ukuphakama | <1000m AMSL, xa≥1000m de-rate ngokuhambelana ne-GB/T3859.2-93 |

1 Ukuwelda kwesigaba esinye

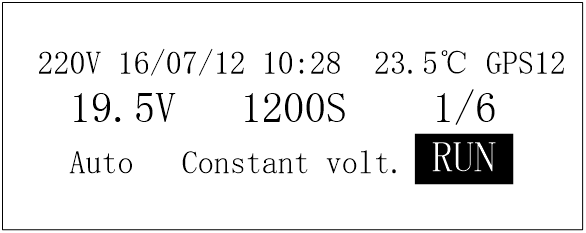

Emva kombane, umatshini wokuwelda ungena ngokuzenzekelayo kwi-welding interface njengoko kuboniswe ngezantsi, hambisa ikhesa ngokushiya ngasekhohlo nasekunene, ucinezele iqhosha elithi "Kulungile" emva kokuba i-cursor ihambela kwiiparamitha ezihambelanayo zikhethiwe, emva koko iiparameters kwi-flicker state.

Ngokusebenzisa amaqhosha aphezulu nasezantsi ukuguqula ixabiso lepharamitha, cofa iqhosha elithi "Kulungile" ukugcina ixabiso ledatha. Ukuba ucinezela iqhosha elithi "ESC" ukulahla ukulungiswa, idatha iya kubuyela kwixabiso ledatha ngaphambi kokuguqulwa. Ukumisela ixabiso "lokumelana nepayipi ye-1.03" lilingana nokuchasana okuhambelana nombhobho.

Emva kokuba iiparamitha ze-welding zisetiwe, hambisa isalathisi kwi-"RUN" kwaye ucinezele "KULUNGILE" ukufaka inkqubo ye-welding.

Qaphela: Beka "i-1.03 ukuchasana kombhobho" ukuya kwi-0 ukuba awukwazi ukuchasana kombhobho, kuphela impazamo yesiphaluka evulekileyo (ukuxhatshazwa kombhobho kukhulu kune-20 ohms okanye i-output current yi-0) ifunyenwe ngexesha lokubona umbhobho. Kodwa olu seto luza kuvala umsebenzi we "alarm yokumelana nombhobho", ke ayinakusetwa xa kuyimfuneko.

2 Izigaba ezininzi zokuwelda

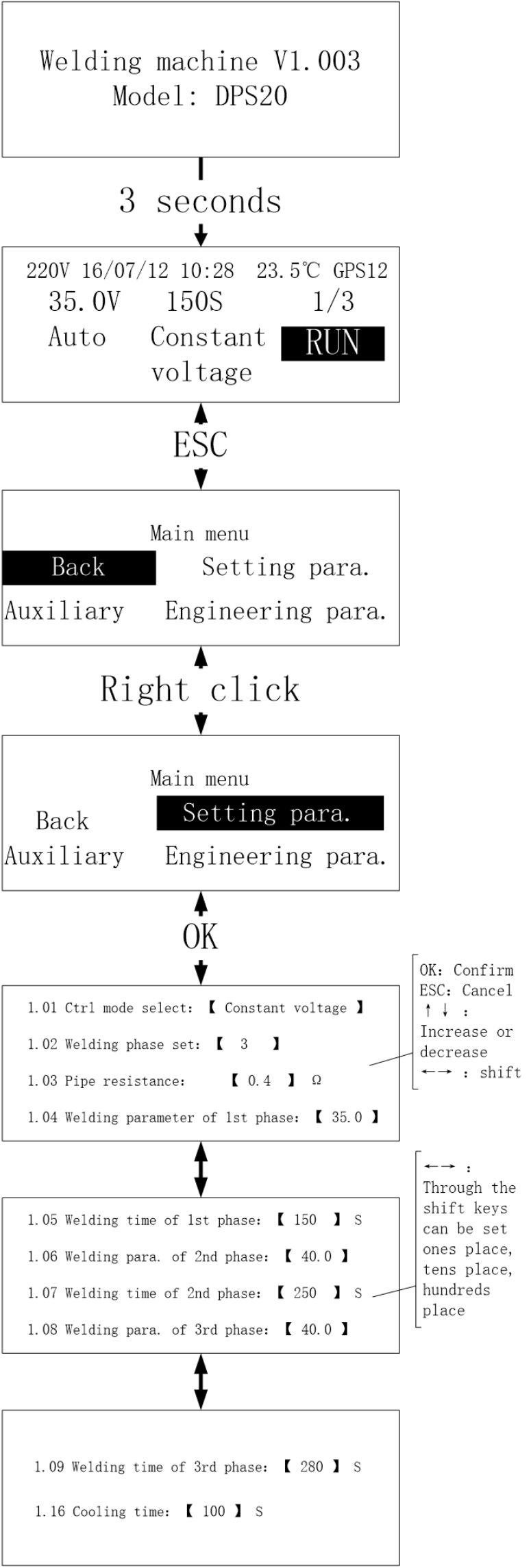

Ukuba inkqubo yombhobho idinga izigaba ezininzi ze-welding, kuyimfuneko ukuguqula "imimiselo yokumisela" → ixabiso lepharamitha elilingana nexabiso lecandelo elifunwayo "1.02 ukusetwa kwenombolo ye-welding".

Umzekelo: ukuchasana kombhobho 0.4Ω, imodi yombane rhoqo, i-3 welding, isigaba sokuqala: i-35V / 150 imizuzwana, okwesibini: imizuzwana ye-40V / 250, eyesithathu: imizuzwana ye-40V / 280, ixesha lokupholisa yimizuzwana eyi-100.

Okokuqala, kufuneka silungise ixabiso le "1.02 inombolo yesigaba se-welding" ukuya kwi-3, setha ixabiso "1.03 ukumelana nombhobho" ukuya kwi-0.4Ω, setha ixabiso "1.04 iparameters welding" ukuya kwi-35V, uze ubeke ixabiso "1.05 1stixesha welding "ukuya kwimizuzwana 150. Oku kugqiba isigaba sokuqala izicwangciso welding. Ekugqibeleni, kufuneka ubeke ixabiso "1.16 ixesha lokupholisa umbhobho" ukuya kwimizuzwana 100. Kwaye ke ukusetwa iiparamitha welding igqityiwe. Cinezela "ESC" iqhosha ukuze ubuyele ujongano welding yokulinda, unokubona ixabiso leeparameters kunye nezicwangciso zexesha elidlulileyo "cofa i-"Move" kunye nexabiso lexesha elidlulileyo "Kulungile". ukufaka inkqubo yokuwelda Amanyathelo okusebenza abonisiwe ngezantsi:

3 ukuwelda iskenaUkuba umbhobho odityaniswe nekhowudi yebar njengoko kubonisiwe ngezantsi, ungayifunda ngeskena. Iiparamitha ze-bar code ze-welding zilandelayo: i-voltage eqhubekayo: i-39.5V, ixesha le-welding: imizuzwana ye-200, ixesha lokupholisa: imizuzu eyi-15. Emva kokuba umsebenzisi eqhagamshele ngokufanelekileyo, usebenzisa iskena ukuskena ibhakhowudi kwaye iskena siya kwenza isandi esithi "beep", kwaye unokubona ixabiso leeparamitha ze-welding ezihlalutywe yikhowudi yebha kwindawo yokulinda yokulinda. Phawula: 1,Kuphelauhlobo lomatshini we-welding luqulethe "S" kunye nomsebenzi wokuskena umsebenzi wokuxhasa iskena; 2,Ibhakhowudi kufuneka ihambelane nohlobo lwekhowudi yebhaye "3.06 uhlobo lwebhakhowudi"; 3,Kufuneka usebenzise iskena esizinikeleyoixhotyiswe yinkampani yethu. Ingcebiso: i-laser kunye nekhowudi yebha ayikho ngokupheleleyo i-90 degrees, umphumo wokuskena ungcono, i-angle yokuthambeka esebenzayo phezulu nasezantsi yi-± 65 °, i-angle yokuthambeka esebenzayo ephezulu nasezantsi yi-± 60 °, i-rotation esebenzayo ye-tilt angle yi-±42 °. Ikhowudi yebha yokuskena, nceda uvumele i-laser igubungele yonke ikhowudi yebha, kungenjalo awukwazi ukufunda idatha echanekileyo.

Imveliso sisixhobo sokudibanisa esikhethekileyo esisetyenziselwa uxinzelelo lwe-polythene kunye noxinzelelo lwe-electrofusion yombhobho okanye uqhagamshelo lwe-soket.

Thumela umyalezo wakho kuthi:

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

-

I-Skype

-

Phezulu